2025-07-24

In the dynamic world of consumer packaging, visual impact and functionality go hand in hand. Among the innovations supporting this balance is the use of PVC shrink film labels for bottle packaging. Known for their adaptability, cost-effectiveness, and brilliant printability, PVC shrink labels have become a solution for various bottled products, from beverages and condiments to pharmaceuticals and personal care items.

As brands compete on crowded retail shelves and prioritize tamper evidence, customization, and sustainability, PVC shrink labels are proving to be both a practical and strategic choice.

What Are PVC Shrink Film Labels?

PVC (polyvinyl chloride) shrink film labels are heat-sensitive plastic films that contract tightly around the contours of a bottle when exposed to heat—typically during steam or heat tunnel processing. Once shrunk, these labels form a seamless, tamper-evident, and often full-body sleeve around the container.

The major appeal of PVC lies in its shrinkage properties, cost-efficiency, and ability to accommodate complex container shapes. With a shrink rate typically around 60-65%, PVC labels can provide a smooth, form-fitting finish that enhances shelf appeal and functionality.

Key Advantages of PVC Shrink Film Labels

1. Full-Body Coverage for Branding

PVC shrink labels provide 360-degree coverage, allowing for striking graphics and ample space for branding, ingredients, usage instructions, and regulatory information—all on one label. This holistic approach to labeling ensures strong shelf presence and greater visual engagement.

2. Compatibility with Complex Shapes

PVC's flexibility and strong shrink characteristics make it ideal for oddly shaped or contoured bottles. This is especially useful in personal care, health supplements, or specialty beverage packaging where packaging uniqueness is a brand differentiator.

3. Cost-Effective Production

PVC remains one of the affordable shrink label materials available. It is easier to print on using a wide range of printing techniques, including gravure, flexographic, and digital processes, which makes it a versatile option for small and large production runs alike.

4. Tamper-Evident Security

PVC shrink sleeves can be designed with perforated or banded seals at the cap or neck of bottles, creating an effective tamper-evident feature. This is increasingly important for health and safety in the food, beverage, and pharmaceutical sectors.

5. High Print Quality

The clarity and smoothness of PVC film support high-resolution graphics and vibrant colors, helping brands make a memorable impact in the retail environment.

Industry Applications

PVC shrink film labels are widely used in a range of sectors, including:

Beverages: Water, energy drinks, juices, and alcoholic drinks often feature PVC shrink sleeves for branding and tamper evidence.

Pharmaceuticals and Nutraceuticals: Bottled vitamins and over-the-counter medications benefit from the secure and informative nature of shrink labeling.

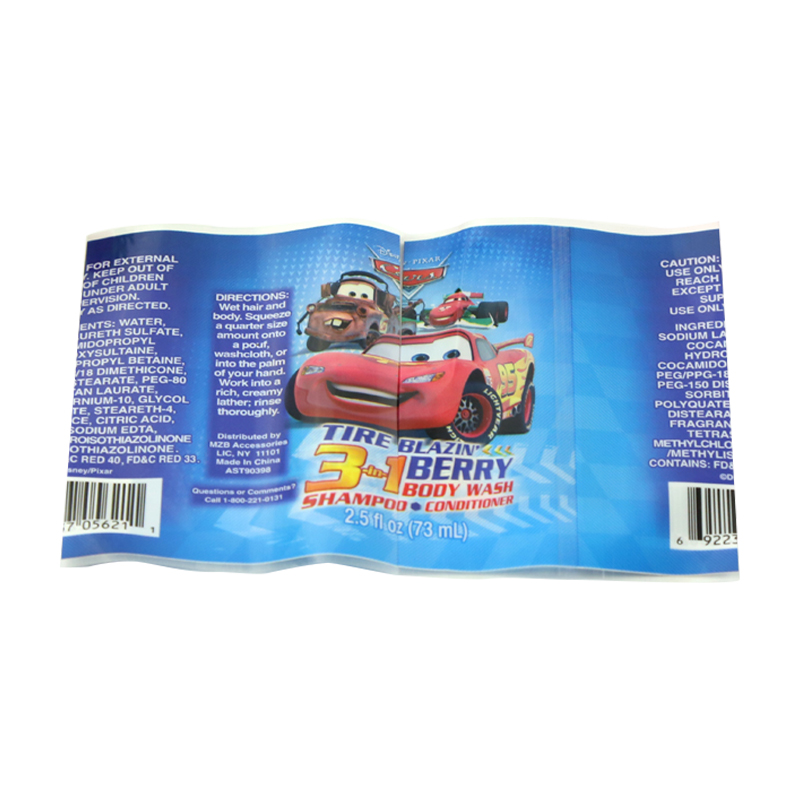

Cosmetics and Personal Care: Shampoo, lotion, and body wash bottles use shrink sleeves to create a clean, professional aesthetic.

Food Products: Sauces, syrups, and condiments are frequently packaged with PVC shrink labels for durability and shelf presence.

Recent Innovations in PVC Shrink Labeling

Manufacturers are increasingly exploring eco-friendlier versions of PVC shrink films with improved recyclability and lower chlorine content. While PVC traditionally posed challenges in mixed recycling streams, efforts are underway to develop cleaner-burning and more recyclable alternatives.

Additionally, high-shrink PVC films are being refined to minimize distortion on containers with sharp angles or ridges, ensuring a smoother application and better visual outcome.

Digital and hybrid printing methods are also gaining traction for short-run customization, enabling brands to personalize labels for specific markets or limited editions without extensive lead times.

Environmental Considerations

While PVC offers many performance benefits, it has come under scrutiny for its environmental impact due to its chlorine content and limitations in recyclability. As a result, many companies are now working with suppliers to explore alternatives such as PETG or OPS when higher sustainability standards are required.

However, for brands focused on cost-effective, high-impact visual branding where recyclability infrastructure is limited or supplementary efforts (like label removal) are in place, PVC remains a widely used and effective option.