2025-07-24

In today’s dynamic packaging landscape, the quest for innovative solutions that combine aesthetic appeal, durability, and security is more vital than ever. Among these innovations, PVC shrink film labels for bottle packaging have emerged as a choice for beverage manufacturers and other industries aiming to elevate their product presentation while safeguarding quality. These labels offer a unique blend of visual impact and functional benefits, driving increased adoption across the global market.

Understanding PVC Shrink Film Labels for Bottle Packaging

PVC (polyvinyl chloride) shrink film labels are thin, flexible plastic films that shrink tightly around bottles and containers when heat is applied. Unlike conventional adhesive labels, shrink film labels provide a full 360-degree coverage, molding seamlessly to the bottle’s contours and enabling vibrant, edge-to-edge graphics. This full-body wrap-around design creates a premium, tamper-evident finish that not only enhances shelf appeal but also improves product security.

The heat-shrinking process involves applying the PVC film to a bottle, then passing it through a heat tunnel where the film contracts uniformly to fit snugly, creating a durable, smooth surface that resists peeling and damage.

Key Advantages of PVC Shrink Film Labels

Full Coverage and Design Flexibility: PVC shrink labels cover the entire bottle surface, including curved or irregular shapes, allowing brands to utilize every inch of packaging for marketing messages, nutritional information, and decorative designs. This freedom boosts brand visibility and consumer engagement.

Tamper Evidence and Security: The tight seal formed by the shrinking film offers inherent tamper-evident properties. Any attempt to remove or alter the label is visibly noticeable, increasing consumer confidence and protecting against counterfeiting.

Durability and Resistance: PVC films provide resistance to water, oils, chemicals, and abrasion, ensuring that labels remain intact and legible throughout the product’s lifecycle—from manufacturing and distribution to retail and consumer use.

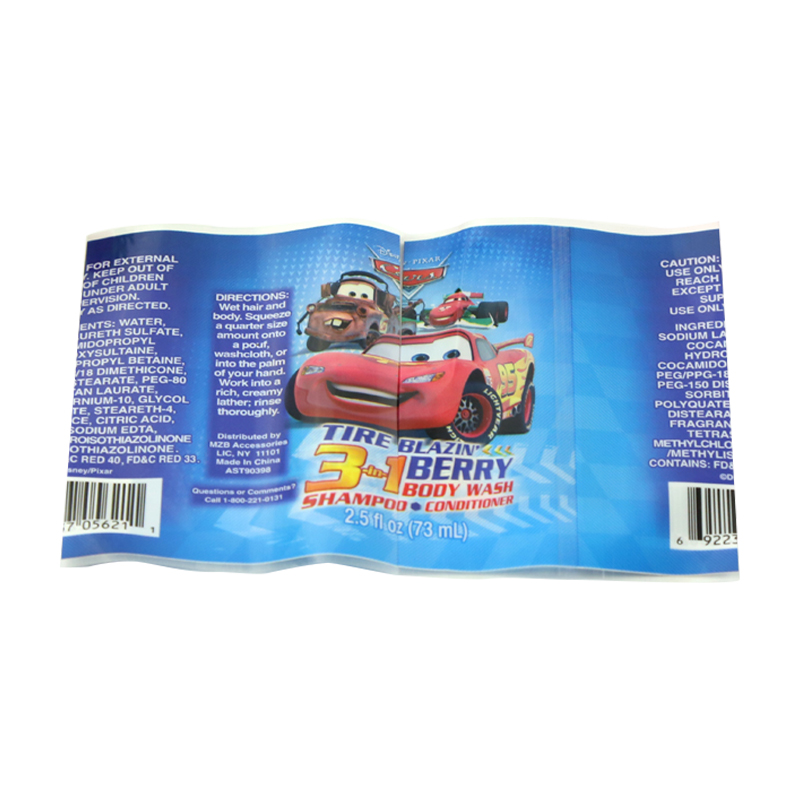

Compatibility with Various Bottles: PVC shrink film labels can be applied to a wide range of materials such as glass, PET, and HDPE bottles, making them versatile for beverage sectors including water, soft drinks, alcoholic beverages, and personal care products.

Cost-Effectiveness: While offering aesthetics and security, PVC shrink labels are relatively cost-effective compared to some alternative labeling and packaging methods, especially in large-scale production runs.

Applications in the Beverage and Consumer Goods Industries

PVC shrink film labels are widely used in the beverage industry, where brand differentiation and product security are paramount:

Water and Soft Drinks: Many bottled water brands employ PVC shrink labels to present clean, crisp designs that withstand moisture and refrigeration.

Alcoholic Beverages: Spirits, wines, and craft beers use shrink labels for sophisticated graphics and tamper-evident sealing, enhancing consumer trust and brand prestige.

Juices and Functional Drinks: PVC labels enable vibrant, colorful branding that communicates freshness and health benefits effectively.

Beyond beverages, personal care products like shampoos, lotions, and household cleaning agents also utilize PVC shrink film labels for their durability and design versatility.

Environmental Considerations and Sustainability

Sustainability is an increasingly important factor in packaging decisions. PVC, traditionally criticized for its environmental impact, has seen improvements in manufacturing and recycling practices. Many suppliers now offer PVC films with lower chlorine content and better recyclability.

Furthermore, the industry is exploring alternatives such as PET shrink films and biodegradable composites that offer similar performance with a smaller ecological footprint. Brands are also adopting thinner films to reduce material use without sacrificing functionality.

Recycling programs focused on separating PVC shrink labels from bottles help improve waste management, although challenges remain in achieving a fully circular PVC lifecycle.

Technological Innovations Driving Market Growth

Advancements in PVC shrink film technology are broadening their capabilities and market appeal:

Enhanced Print Quality: Modern printing techniques such as rotogravure and flexography allow for high-resolution, photorealistic images with vibrant colors and complex graphics.

Special Effects and Finishes: Matte, gloss, soft-touch, and holographic finishes add tactile and visual differentiation to products, elevating consumer appeal.

Improved Shrink Performance: New formulations provide faster, more uniform shrinking at lower temperatures, increasing production efficiency and reducing energy consumption.