2025-07-24

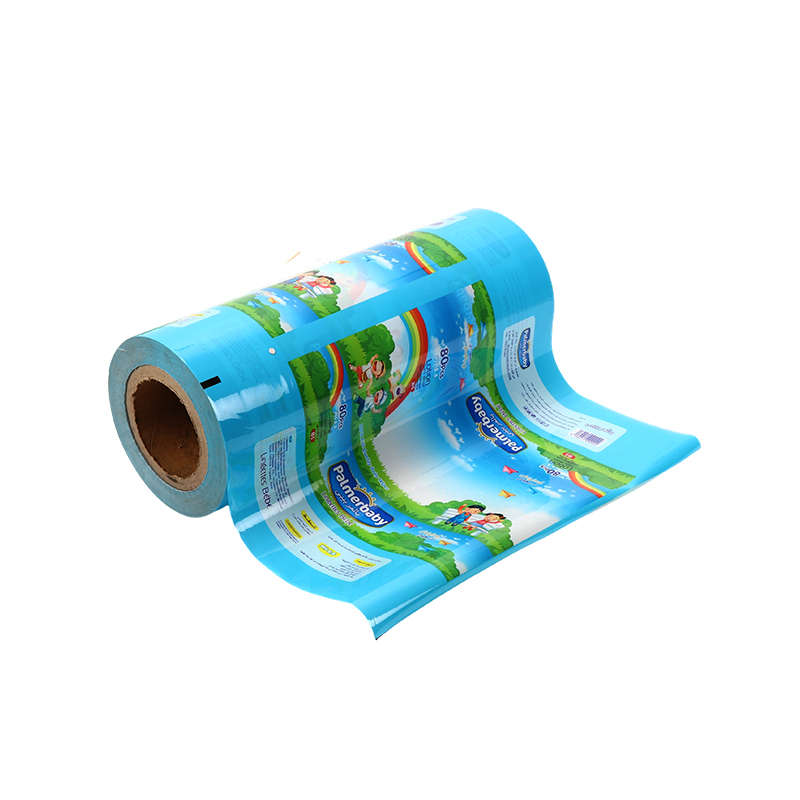

In the rapidly expanding wet wipes market, packaging innovation plays a pivotal role in ensuring product freshness, user convenience, and brand differentiation. Among the key components that contribute to the success of wet wipes products is the large roll wet wipes composite packaging film—a foundational material that enables efficient production and packaging performance. As manufacturers seek to optimize production while maintaining high standards of quality and protection, large roll composite films have become indispensable in wet wipes packaging.

What Is Large Roll Wet Wipes Composite Packaging Film?

Large roll wet wipes composite packaging film refers to multilayer laminated films supplied in wide, continuous rolls designed specifically for high-speed wet wipes packaging machinery. These films are engineered to provide an effective barrier against moisture, oxygen, and contaminants while offering mechanical strength, flexibility, and printability.

Unlike pre-formed bags or smaller packaging units, large roll films enable manufacturers to streamline their packaging lines by feeding continuous material directly into form-fill-seal machines, which then convert the film into individual wet wipes packages or pouches. This roll-to-package process increases production speed, reduces downtime, and lowers packaging costs.

Composite Film Structure and Material Composition

The large roll composite packaging film typically consists of multiple layers laminated together to combine various material properties:

Outer Layer: Usually polyester (PET) or polypropylene (PP), this layer provides printability and protection from physical damage. It supports high-quality graphics, brand messaging, and regulatory information.

Barrier Layer: Materials such as aluminum foil, metallized films, or ethylene vinyl alcohol (EVOH) serve as moisture and oxygen barriers, crucial for maintaining the wet wipes’ moisture content and preventing contamination.

Sealant Layer: The inner layer, often polyethylene (PE) or linear low-density polyethylene (LLDPE), enables heat sealing during packaging, ensuring leak-proof and airtight closure.

The precise formulation and thickness of these layers can be customized to meet specific product needs, such as enhanced barrier performance for disinfectant wipes or softer films for delicate baby wipes.

Advantages of Using Large Roll Composite Films

High Production Efficiency: Supplying packaging film in large rolls facilitates continuous operation of automated packaging machinery, reducing material changeovers and increasing output rates. This efficiency is vital for meeting the growing demand for wet wipes globally.

Consistent Quality and Performance: Large roll films are produced under strict quality control conditions, ensuring uniform barrier properties, thickness, and sealing strength across the entire roll. This consistency packaging defects and product waste.

Customization and Branding Opportunities: The outer printable surface of the film supports vibrant, high-resolution graphics using flexographic or gravure printing techniques. Brands can customize packaging designs to capture consumer attention and comply with labeling regulations.

Versatility: Large roll composite films can be adapted for various wet wipes packaging formats, including flat pouches, stand-up pouches, or flow packs. This flexibility allows manufacturers to diversify their product offerings with changes to the supply chain.

Improved Shelf Life: The multilayer barrier properties effectively protect wet wipes from moisture loss and external contamination, extending product shelf life and enhancing customer satisfaction.

Industry Applications and Trends

Large roll wet wipes composite packaging films are widely used in multiple wet wipes categories:

Baby Care Wipes: Require gentle films with high moisture retention to keep wipes soft and safe for sensitive skin.

Disinfectant and Medical Wipes: Demand robust barrier films to protect against evaporation of active ingredients and maintain sterility.

Cosmetic and Personal Care Wipes: Benefit from customizable films that offer aesthetic appeal and functional resealable features.

Household Cleaning Wipes: Often packaged in durable films that withstand handling and maintain moisture.

With consumers placing increasing emphasis on hygiene and convenience, the demand for wet wipes—and consequently for efficient, high-quality packaging films—is projected to grow significantly.