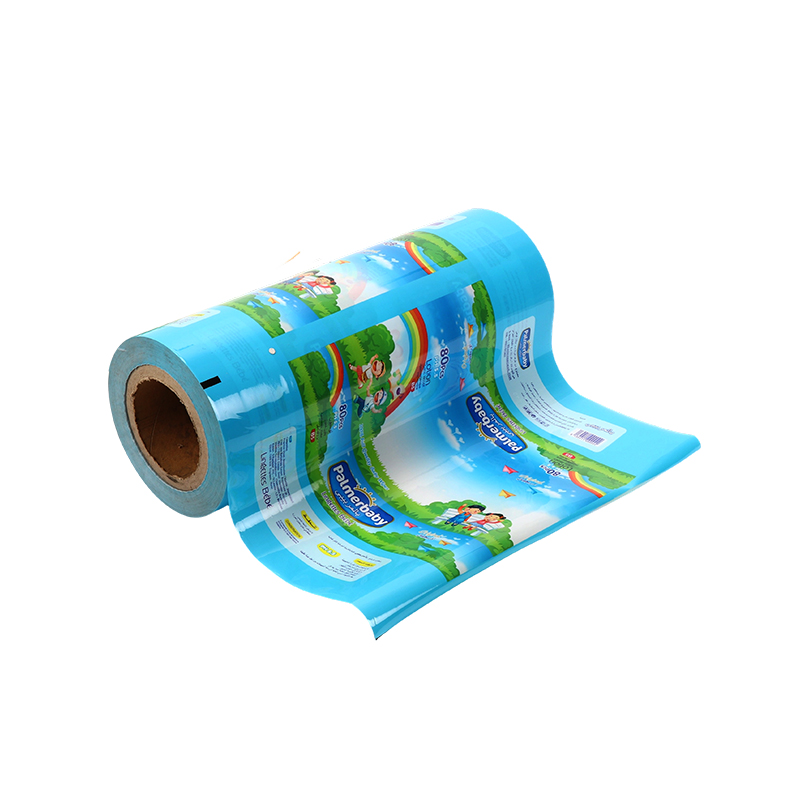

Material Composition and Performance

The No Fading Strong Composite Packaging Film integrates two essential layers: a high-quality PET printing film and a specially formulated milky white PE. The PET film undergoes high-definition Gravure printing, known for its vibrant finish and sharp graphic reproduction. What sets this product apart is its excellent surface adhesion—ensuring that the printed design remains intact without fading or smudging during handling or storage.

The PE layer is designed for low-temperature sealing, making it highly compatible with automated packaging lines. It provides high tack, ensuring secure and efficient sealing without the risk of leaks or breakage. This low-temperature, high-adhesion property ensures the packaging remains intact during production and throughout the product’s shelf life.

Key Features and Advantages

1. No Color Fading

One of the standout features of this film is its excellent resistance to color fading. Whether exposed to light, pressure, or friction, the printed layer maintains its original appearance thanks to superior surface adhesion. This ensures a consistent and professional brand presentation at all stages of distribution.

2. Strong Composite Bonding

The No Fading Strong Composite Packaging Film is developed with a focus on composite strength. The PET and PE layers are bonded using advanced lamination techniques, ensuring a durable and reliable seal. This strong bonding prevents delamination, even under stress, making it ideal for high-speed packaging lines and long-term storage.

3. Designed for Wet Wipe Packaging

This packaging film is engineered specifically for wet wipe applications. Its high barrier properties help retain moisture and prevent leakage, which is essential for maintaining product quality. The film is water-resistant, flexible, and tear-resistant, making it a suitable choice for single-use or refillable wet wipe pouches.

4. Fast and Efficient for Automation

With a width of 32cm, the film is supplied in roll form for use in automatic packaging machines. Its consistent thickness and excellent heat-sealing response help improve packaging speed, reduce material waste, and minimize equipment downtime. The film is optimized for smooth feeding and clean cuts during production.

5. Leak-Proof and Secure

The PE layer used in the No Fading Strong Composite Packaging Film exhibits high seal strength, reducing the likelihood of leaks. This ensures that the contents—especially wet products like wipes—remain properly contained from factory to end user.

Applications and Use Cases

The primary application for the No Fading Strong Composite Packaging Film is in the production of wet wipe packaging bags. However, its properties also make it suitable for other personal care or hygiene products requiring moisture retention and durable sealing. Its high print quality allows brands to showcase vibrant packaging designs that appeal to consumers while offering practical protection and functionality.

The No Fading Strong Composite Packaging Film offers a balanced combination of strength, efficiency, and visual appeal. With robust adhesion, excellent sealing properties, and colorfast printed surfaces, it supports both operational efficiency and brand consistency.