2025-07-24

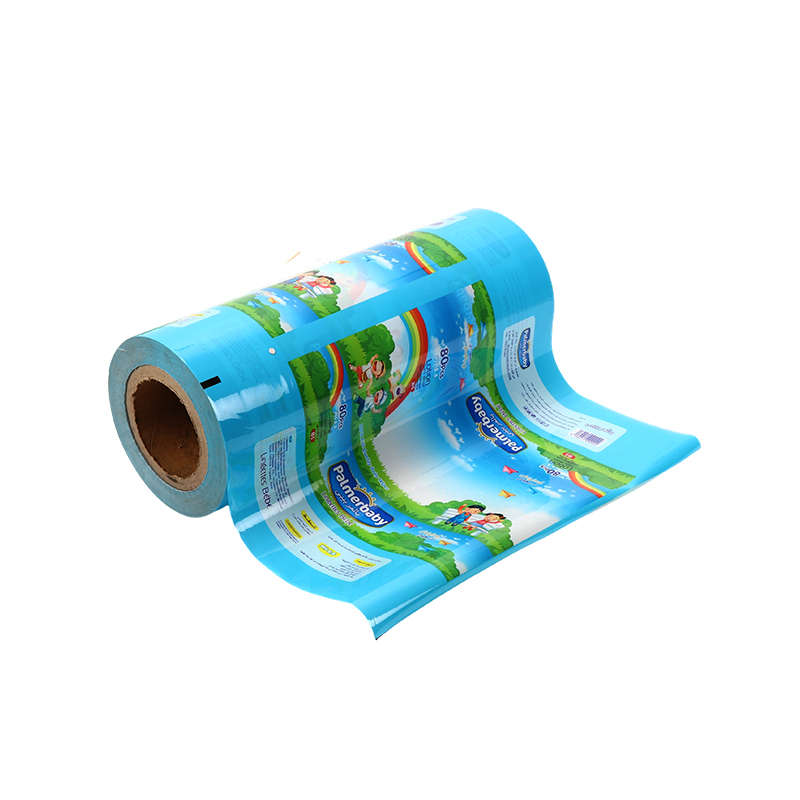

The wet wipes industry has witnessed rapid growth in recent years, fueled by rising consumer awareness of hygiene, expanding applications, and a shift towards convenient personal care and cleaning solutions. Central to meeting the increasing demand is the role of packaging materials, which ensure product freshness, usability, and protection throughout the supply chain. Among these materials, large roll wet wipes composite packaging film stands out as a vital component—offering manufacturers enhanced production efficiency, performance, and design versatility.

Understanding Large Roll Wet Wipes Composite Packaging Film

Large roll wet wipes composite packaging film refers to wide, continuous sheets of multi-layer laminated materials designed specifically for the packaging of wet wipes. These composite films combine various polymers such as polyethylene (PE), polypropylene (PP), polyester (PET), and sometimes metallized layers, creating a robust barrier that protects wet wipes from moisture loss, contamination, and mechanical damage.

Supplied in large rolls, this packaging film enables high-speed, automated packaging processes, supporting the mass production of wet wipes products with consistent quality and precision.

Advantages of Using Large Roll Composite Films

High Production Efficiency: Large rolls allow packaging machines to operate continuously with fewer roll changes, downtime and increasing throughput—essential for large-scale wet wipes manufacturing.

Barrier Properties: The multi-layer construction ensures protection against water vapor, oxygen, and external contaminants, preserving the moisture and hygiene of wet wipes throughout their shelf life.

Customization Flexibility: Large rolls can be printed with high-resolution graphics and brand messaging before being converted into packaging pouches or sachets, enabling vibrant, eye-catching designs.

Material Strength and Durability: The composite layers provide resistance to punctures, tears, and abrasions during packaging, transportation, and handling, reducing product damage and waste.

Cost-Effectiveness: Bulk supply of large rolls typically reduces material costs and simplifies inventory management compared to smaller packaging formats.

Applications and Market Demand

Large roll wet wipes composite packaging film is essential across various wet wipes segments:

Baby Care Wipes: Soft, gentle wipes packaged in films that maintain moisture and softness.

Personal Hygiene Wipes: Facial, antibacterial, and intimate wipes requiring high hygiene standards and convenient resealability.

Household Cleaning Wipes: Durable packaging that withstands frequent opening and closing.

Medical and Disinfectant Wipes: Films that ensure sterility and prevent contamination.

The growing demand for ready-to-use, disposable wipes in households, healthcare settings, and public spaces continues to drive the need for reliable packaging films produced on a large scale.

Technological Innovations in Composite Film Production

Advancements in materials science and manufacturing techniques have improved the performance and sustainability of large roll wet wipes composite films:

Enhanced Barrier Layers: Incorporation of ethylene vinyl alcohol (EVOH) or metallized films increases protection against oxygen and moisture without adding bulk.

Eco-Friendly Films: Development of recyclable mono-material composites and bio-based films addresses environmental concerns while maintaining packaging integrity.

Digital and Flexographic Printing: High-quality printing on large rolls offers brands vibrant, customizable graphics that boost shelf appeal and consumer engagement.

Lightweight Design: Thinner films with optimized layer structures reduce material usage without compromising durability, contributing to cost savings and lower environmental impact.

Challenges and Industry Solutions

While large roll composite films offer numerous benefits, challenges include:

Recyclability: Multi-layer films are traditionally difficult to recycle due to their laminated structure; ongoing research focuses on mono-material composites to enhance recyclability.

Production Precision: Maintaining consistent film thickness, seal strength, and print quality across wide rolls requires advanced manufacturing controls.

Supply Chain Management: Ensuring timely delivery and storage of large roll materials necessitates efficient logistics and warehousing solutions.

Industry stakeholders are collaborating to overcome these challenges by investing in R&D, upgrading equipment, and implementing sustainable sourcing practices.