2025-07-24

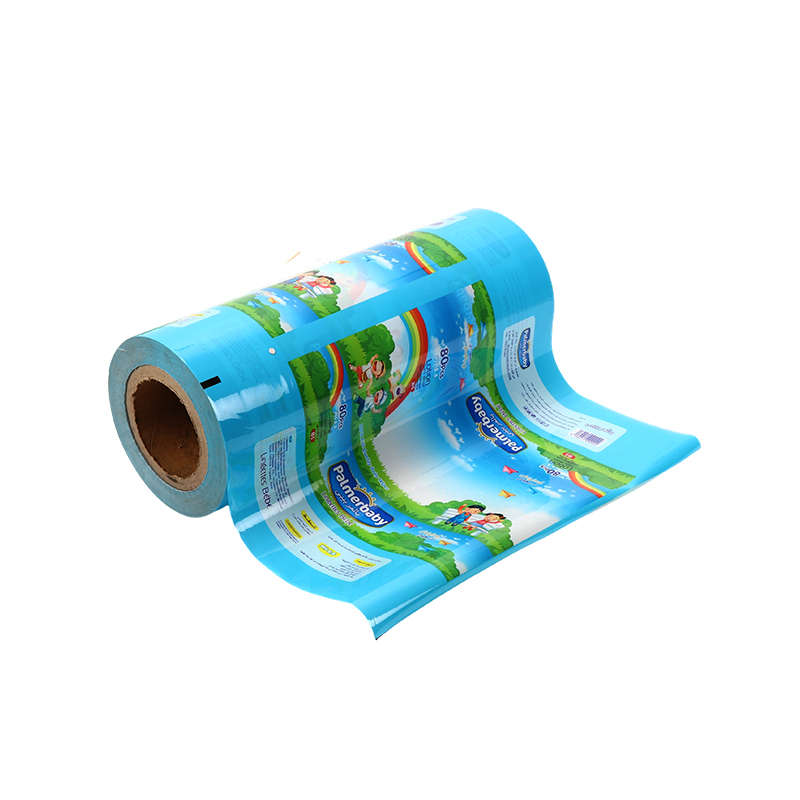

As the global wet wipes market expands rapidly across personal care, healthcare, and household sectors, packaging manufacturers are under increasing pressure to deliver materials that balance durability, cost-efficiency, and product protection. Rising to meet this challenge, the Large Roll Wet Wipes Composite Packaging Film has become a key enabler of modern wet wipes production—offering enhanced performance and streamlined manufacturing benefits.

This specialized composite film, combining a high-grade PET printing layer with a milky white polyethylene (PE) composite substrate, is reshaping how manufacturers package and present wet wipes. Its advanced construction meets the stringent demands of moisture retention, print clarity, and mechanical resilience, making it an essential material for large-scale production.

Understanding the Composition and Functionality

The Large Roll Wet Wipes Composite Packaging Film is engineered through a multi-layer lamination process:

PET Printing Film: The outerlayer, polyethylene terephthalate (PET), provides surface smoothness and dimensional stability. This allows for high-resolution printing, enabling vibrant branding and detailed graphics to attract consumer attention on crowded retail shelves.

Composite Milky White PE Layer: Beneath the PET layer lies a milky white polyethylene film. This layer functions as the primary moisture barrier, preventing evaporation of the wipes’ liquid content. Its composite nature enhances tear resistance and puncture strength, protecting the wipes throughout distribution and use.

The combination of these materials delivers a packaging film that is not only visually appealing but also highly functional, capable of preserving product quality while withstanding the rigors of automated packing machinery.

Why Large Roll Composite Films Are Gaining Industry Momentum

1. Improved Manufacturing Efficiency

Large rolls of composite film allow manufacturers to optimize production runs. The continuous feed format reduces machine downtime and waste compared to smaller sheet formats or less flexible materials. This results in higher throughput, lower labor costs, and more consistent sealing and cutting quality.

2. Barrier Performance

Moisture retention is in wet wipes packaging. The milky white PE layer’s barrier properties prevent wipes from drying out, ensuring they remain soft and effective through their shelf life. Additionally, the film’s robust structure offers protection against external contaminants such as dust and microbes.

3. High-Quality Print and Branding Opportunities

With PET as the printing surface, this composite film supports advanced printing techniques including flexographic, gravure, and digital printing. Brands can produce sharp, vibrant images and text with color fidelity. The milky white background enhances contrast, making product names and key messaging stand out.

4. Mechanical Durability

Packaging films must resist tearing, punctures, and stretching during shipping, handling, and consumer use. The composite construction of these large rolls ensures a strong yet flexible film that protects the product without compromising packaging integrity.

Applications Across the Wet Wipes Industry

The versatility of large roll composite films makes them ideal for a wide spectrum of wet wipes products:

Baby Care Wipes: Demanding gentle yet effective packaging, these wipes benefit from the film’s moisture retention and soft appearance.

Personal Hygiene Wipes: Facial and intimate wipes packaged in large roll films maintain freshness and convey a feel.

Household Cleaning Wipes: Durable packaging that withstands frequent use and exposure to chemicals is essential here.

Industrial and Medical Wipes: Protective films ensure sterility and product stability in professional environments.

Market Trends Driving Demand

The increased consumer focus on hygiene and convenience—fueled by the global health landscape—has accelerated wet wipes consumption worldwide. Simultaneously, retailers and manufacturers seek packaging materials that enable sustainability without sacrificing quality.

In response, suppliers of large roll composite films are innovating to:

Incorporate recyclable and bio-based components to reduce environmental impact.

Optimize film thickness to minimize plastic use while maintaining performance.

Enhance barrier properties with new coatings and lamination technologies.

These developments are critical as brands face stricter regulatory requirements and growing consumer scrutiny over packaging waste.