2025-10-03

Open a canister of wipes on a changing table, and the thing you notice is the cool, faintly scented puff of air that escapes. That tiny whisper of freshness is not an accident—it is the result of a silent, daily battle fought by the Wet Wipes Packaging Film wrapped around every sheet. Consumers rarely think about the film once the package is open, yet its chemistry, structure, and sealing precision decide whether the wipe that touches a baby’s skin or cleans a traveler’s hands is still a moist, sterile cloth or a dried-out, compromised rag. Understanding how the film keeps each wipe fresh reveals why some brands cost more, why others disappoint, and why the package is as critical as the lotion inside.

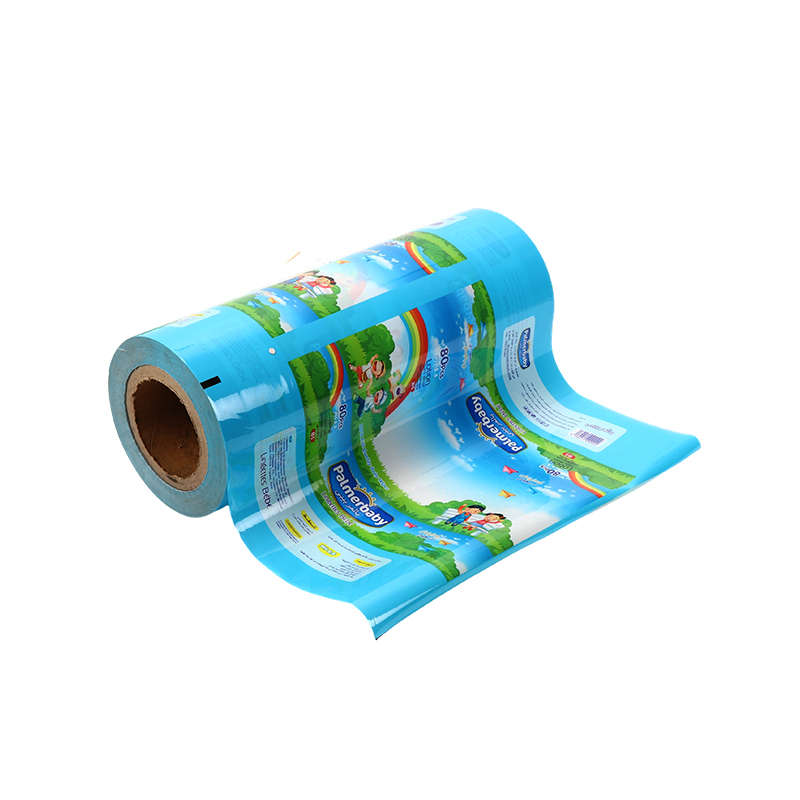

Freshness begins with water retention. A typical wipe is 90 % purified water, preservatives, and a micro-emulsion of silicones or fruit extracts. If even 2 % of that water evaporates, the cloth loses flexibility and the preservative system can crash, allowing yeast or mold to bloom. Wet Wipes Packaging Film counters this loss with a five-layer laminate only 85 microns thick. The outer skin is reverse-printed oriented polypropylene (OPP) for scuff resistance and shelf appeal. Next comes an adhesive tie layer, then an aluminum core only 7 microns thick—thin enough to flex, thick enough to block virtually all water vapor and ultraviolet light. A fourth layer of low-density polyethylene provides heat-sealability, and the innermost skin is food-grade linear polyethylene engineered to resist lotion absorption. Taken together, the structure posts a water-vapor transmission rate (WVTR) below 0.1 g m⁻² day⁻¹, meaning a 60-count pack loses less than one drop of water per month at room temperature.

Yet barrier layers mean nothing if the seal fails. Consumers intuitively check the lid, but the critical seal is the horizontal fin seal running under the label. High-speed pack lines use 180 °C jaws to fuse the polyethylene inner layers in 0.18 seconds; the challenge is to avoid “channel leakers,” microscopic wrinkles that act as capillaries. brands run 100 % seal inspection with infrared cameras that detect temperature dips of less than 2 °C, rejecting packs whose seal width falls below 3 mm. The payoff: after being trucked across the Arizona desert in July, randomly sampled wipes still register 97 % of their original moisture.

Oxygen is the second enemy of freshness. Even when wipes stay wet, oxidation can turn gentle phenoxyethanol into pungent benzaldehyde, producing that dreaded “old-wipe” smell. The aluminum layer again plays hero, cutting oxygen transmission to 0.05 cm³ m⁻² day⁻¹, an order of magnitude lower than metallized polyester alternatives. Some good films go further, embedding nanoscale clay platelets that create a “tortuous path,” reducing oxygen ingress another 40 % without adding metal. The result is a wipe that smells as neutral on day 90 as on day one.

Consumers often ask why resealable labels matter if the film is so robust. The answer is micro-cycles. Every time a lid is opened, a 30 mL gulp of ambient air rushes in, raising relative humidity inside the pack by 5–7 %. Over a month of diaper changes, that is 300 intrusion events. Modern flip-top lids incorporate a springy TPE gasket that rebounds in 0.3 seconds, cutting intrusion volume to 8 mL. Paired with a label adhesive formulated to tolerate 30 % lotion contamination, the system keeps internal humidity variation under 2 %, preventing the osmotic shock that can draw water out of the wipes and into the headspace.

Sustainability pressures are stretching the definition of freshness. European parents now ask whether a biodegradable wipe can stay moist in a compostable pack. Start-ups are experimenting with monomaterial polypropylene films that use silica oxide coatings instead of aluminum; WVTR rises to 0.4 g, still acceptable for 42-day use cycles. In parallel, high-melt-strength PP allows the entire pack to be mechanically recycled, turning used film into drainage pipes. Early trials show that after 12 weeks on shelf, wipes in these next-gen packs retain 94 % moisture—proof that freshness and eco-design can coexist.

So, how fresh is each wipe? If the brand invests in multi-layer barrier film, validated heat seals, and a gasketed reclosure, the wipe that surfaces at 3 a.m. is chemically identical to the one quality-control technicians approved weeks earlier. If corners are cut—thinner aluminum, narrower seals, generic labels—the wipe may feel fine, but the last ones will be dry, discolored, and potentially unsafe. The package is not a mere wrapper; it is an active guardian. Next time you lift that lid, pause to notice the quiet engineering in your hand: a 5-gram film standing between a pristine wipe and the entropy of the outside world.